Find Plywood on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

New Products

| Min. Order: | 1 Set/Sets |

|---|

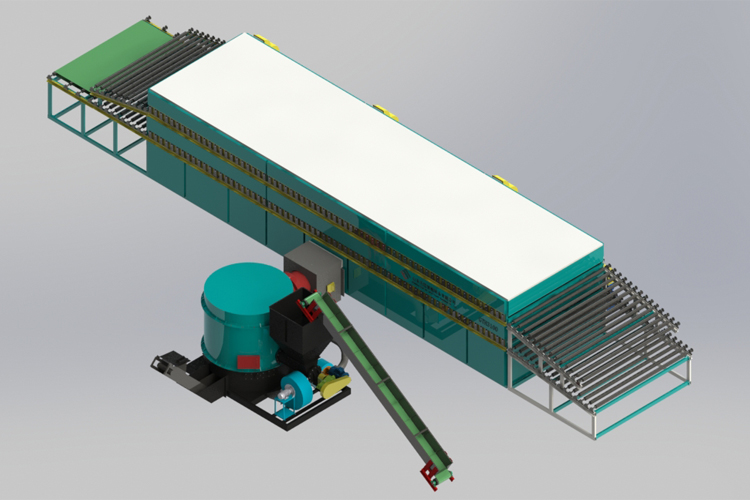

Parameter Model | DHS20M | DHS24M | DHS28M | DHS32M | DHS36M | DHS40M |

Work width(m) | 3 | 3 | 3 | 3 | 3 | 3 |

Deck | 2 | 2 | 2 | 2 | 2 | 2 |

Veneer thickness(mm) | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 |

Heating area (m) | 16 | 20 | 24 | 28 | 32 | 36 |

Cooling area (m) | 4 | 4 | 4 | 4 | 4 | 4 |

Initial water content(%) | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 |

Finished water content(%) | 10 | 10 | 10 | 10 | 10 | 10 |

Drying capacity (m³/h) | 0.8-1.1 | 1.1-1.4 | 1.5-1.8 | 1.8-2.2 | 2-2.5 | 2.4-2.7 |

Heat exhaustion(10000 kcal) | 28-38.5 | 38.5-49 | 52.5-63 | 63-77 | 70-87.5 | 84-94.5 |

Total power (kw) about | 66 | 77 | 88 | 114 | 117 | 121 |

Overall size LxWxH(m) | 25*4.5 | 29*4.5 | 33*4.5 | 37*4.5 | 41*4.5 | 45*4.5 |

Product Categories : Veneer dryer machine > Veneer dryer machine