Find Veneer Drying Machine, Plywood Core Veneer Dryer, Face Veneer Dryer on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

New Products

| Min. Order: | 1 Set/Sets |

|---|

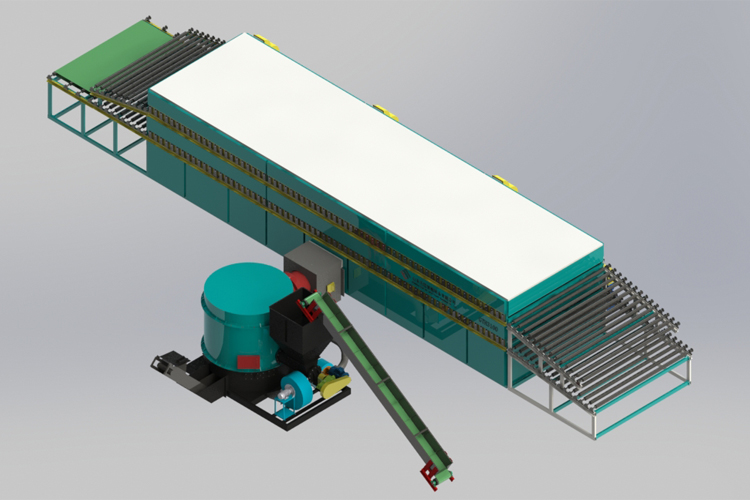

Model No. | GTH30-36 | |

Type | Veneer Roller Dryer | |

Application | Core Veneer Drying | |

Number of Sections | 8 | |

Number of Decks | 1 | |

Working Width | 3000mm | |

Roller material | Q235B, φ89 steel pipe | |

Heating section length | 32m | |

Cooling section length | 4m | |

Veneer thickness | 0.6-8mm; | |

Initial moisture content | 50-80% | |

Final moisture content | 10%(adjustable based on the requirement) | |

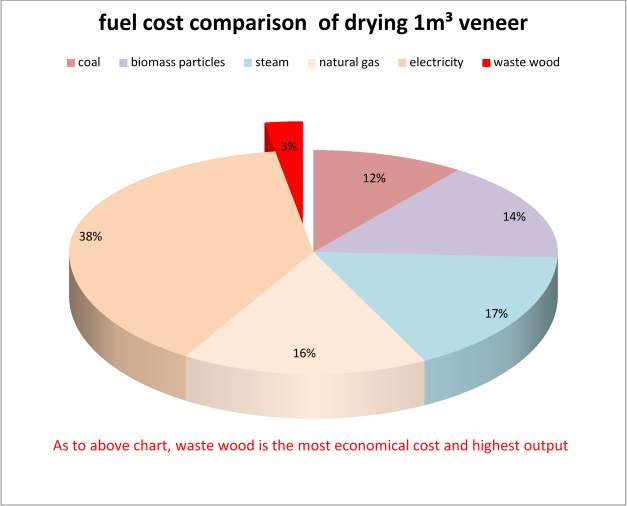

Heating material & drying temperature | Waste wood, 120-180℃ adjustable | |

Drying capacity (m³/h) | 2.2 m³/h | |

Heat Requirement (10000 Kcal/h) | 35 | |

Veneer delivery speed | 5-22m/min (adjustable) | |

Hot air fan | Power: 7.5KW(8pc) | |

Cold air fan | Power: 7.5KW(1pc) | |

Air intake fan | Power: 11KW(1pc) | |

Traction motor | Power: 5.5KW frequency control (1pc) | |

2 Ton Biomass Burner | Power: 15KW | |

Total power | 99KW | |

Actual Electricity Consumption | About 69Kw per hour | |

Overall Dimensions (L*W*H) | 42X9X2m | |

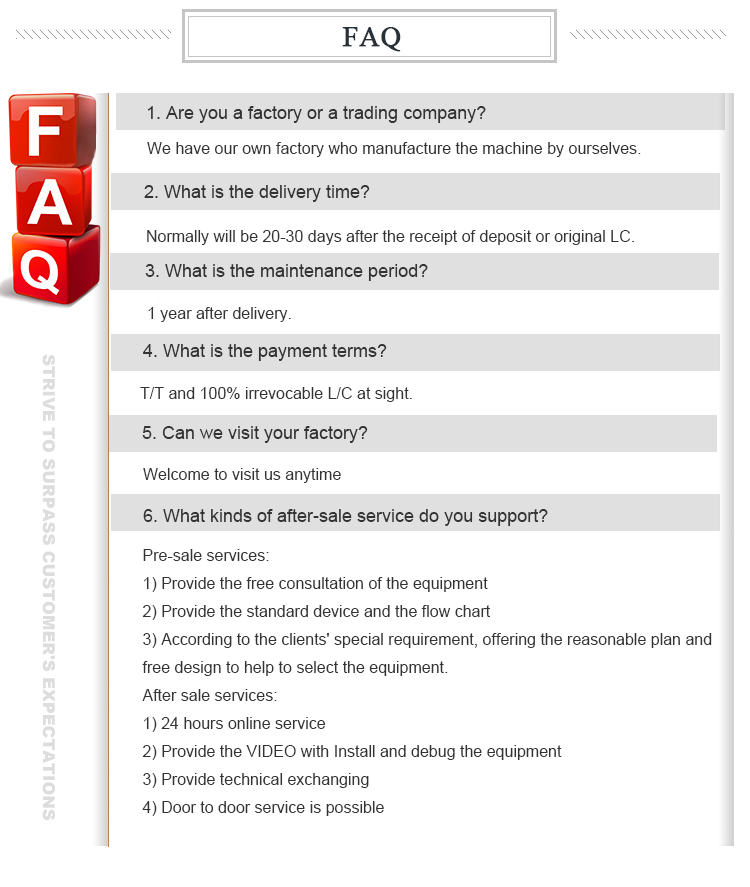

All specifications, dimensions & design characteristics are subject to change without prior notice. | ||

Product Categories : Veneer dryer machine > Roller veneer dryer machine